“There are no good deminers, just old deminers! You can only make one mistake in our field.” General Patrick Alabergère - Ouest France

Our services include the study of several types of data:

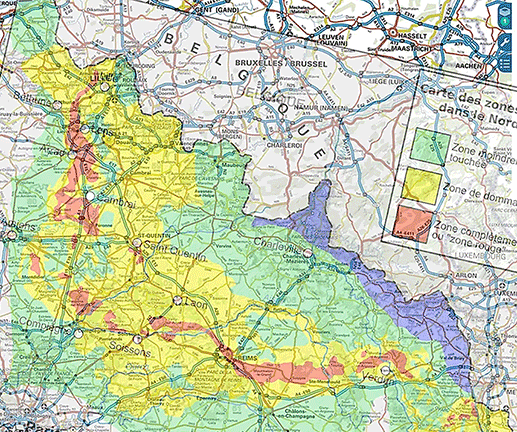

Explosion risk zoning

Is my land affected by an explosion risk?The extent of the explosion risk in France is evaluated according to several considerations:

- Elements related to combat during the last major conflicts:

- - The Franco-Prussian War of 1870

- - Conflicts during WWI

- - Conflicts during WWII

- Elements related to munitions destruction operations following World War II.

- Elements related to the operation of industrial facilities for the production of munitions and/or explosives.

- Elements related to explosive contamination of shooting ranges of the French Ministry of the Armed Forces (Ministère des Armées).

Historical research on explosives

The extent of the explosion risk in France is evaluated according to several considerations:This study must provide a precise analysis of the site subject to the request, taking into account the various sources of contamination possible: - The Franco-Prussian War (1870) - World War I (1914-1918) - World War II (1939-1945) - Training sites of the armed forces before, during, or after these three conflicts - active military sites - abandoned military sites - any clearance or removal of munitions carried out on or immediately near a site - areas used to destroy munitions following the above mentioned conflicts - sites where munitions have been produced

An analysis of potential contamination is added to this geographical and historical analysis, i.e. the types of munitions likely to be found on the site, their possible depth of burial and also perhaps their location (notably in the case of bombings that took place during World War II). Following this analysis, a clear conclusion is issued to the project owner as to the inherent risk of interaction between the future use of the site and the presence of unexploded explosive ordnances (UXO) and/or explosive remnants of war (ERW) present in the subsoil.

Explosive safety study.

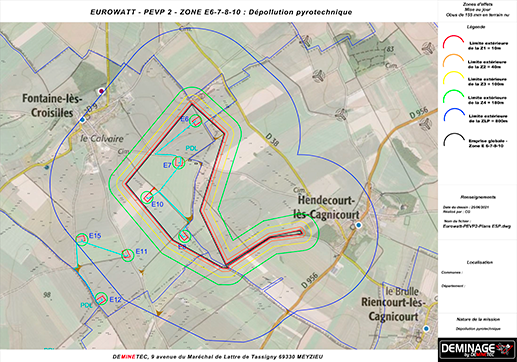

Following the historical research, and before any operations are carried out, an explosive safety study is performed.This safety study is divided into two parts according to the risks applicable to the two major operations that follow:

- The first part covers operations to prepare the land and diagnosis of explosive contamination.

- The second part covers the explosives clearance operations themselves.

The first part is meant to precisely study the conclusions of the historical research and mainly focuses on identifying whether or not there is a “surface” explosion risk. This means whether it is possible to find munitions directly on the ground, which would cause a risk for operators performing brush clearing and deconstruction works, as well as explosive contamination diagnostics.

If this is not the case, the previously mentioned works may be carried out without submission of a safety study to the relevant French authorities.

If the surface risk cannot be excluded, operations to prepare the land and diagnostics will require preparation and submission of a safety study.

concerning the second part (clearance of explosive contamination), it requires preparation of a safety study in all cases. It is based on an analysis of the explosion risks encountered by workers and the environment of the worksite at each of the operational phases.

Compensatory or particular protective measures are likely to be implemented, depending on the conclusions of this analysis.

Relations with administrative bodies

Across the entire country, the search, neutralization, removal, and destruction of munitions, mines, traps, vehicles and explosives are, as per article R. 733-1 of the Internal Security Code subject to the competency of:- Specialized services of the ministry in charge of civil security, on civil territory.

- Specialized services and formations of the Ministry of Defense, on territory under its responsibility, in territorial waters and on coastlines, excluding non-military ports.

However, and as per Decree No. 2010-1260 of 22 October 2010 modifying Decree No. 2005-1325 of 26 October 2005 relative to safety rules applicable during works carried out in the context of an explosives clearance worksite, these operations may be performed partially or in their totality by private companies.

DEMINETEC works within this specific context.

For all intrusive phases, our operations will require a conciliation meeting with the relevant services of the French State, under partial delegation (notably outside the jurisdiction of the Ministry of Defense).

This meeting will make it possible to define the interfaces between DEMINETEC and the services of the State, notably to define the phasing of operations and any resources to be provided.

Environmental analysis

The explosion safety study analyzes the explosion risks encountered by workers and the environment of the worksite at each of the operational phases.This analysis must make it possible to provide a spatial view of the worksite environment in order to define if the risks faced by the various installations located near the site are controlled in compliance with regulation.

The analysis of installations depends on several points:

Based on these 5 points, the environment will be analyzed including areas 50 to 1200 m around the site that is subject to the work. Depending on the position of the various installations and their categorization (roads, fields, housing, daycare facilities, schools, stadiums, etc.), some of them may request compensatory measures to guarantee their safety.

These measures may be of two types:

Concerning external measures, they shall be presented to the prefectoral authority in all cases for application on the impacted installations.

Ballistic protections

To reduce the areas affected by explosives clearance works, DEMINETEC is able to install protective screens or ballistic protections.The protective screens are intended to reduce the effects of accidental detonation of munitions (blast effect, projectiles, or thermal effect). The screens we use can be made of several types of material and can be adapted to meet all size constraints (type of munition), position constraints (depth, subsoil environment) and orientation constraints (one or more installations to protect).

As for the ballistic protections developed by DEMINETEC, there are two types (depending on the reference munition: 155 mm or 250 kg bomb) and they are intended to stop the effect of initial projectiles and reduce or orient the blowout effect.

These protections, weighing a few metric tons or up to several thousand tons, depending on the munition, can take more or less time to install (from 10 min. to 2 days) and sometimes require prior preparation of the terrain.