Our interventions are carried out following an explosive safety study that aims to precisely describe the operations we perform, the number of mine disposal teams sent out and their positions in the field.

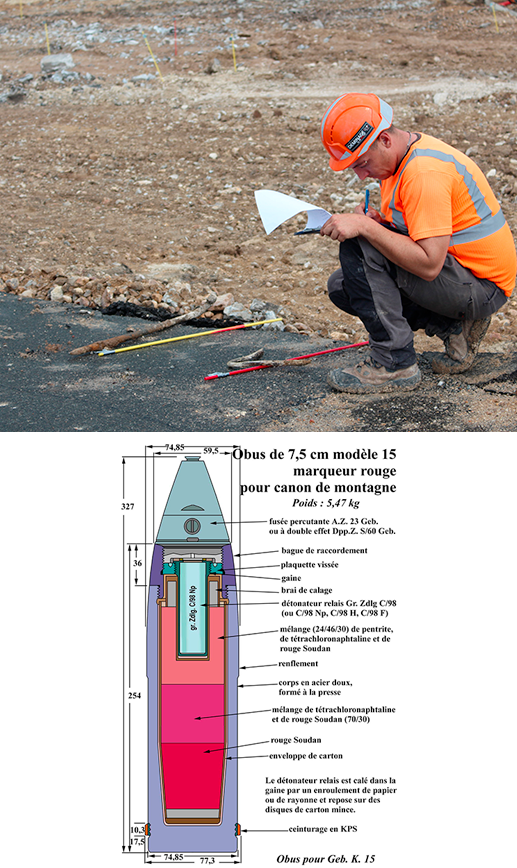

Explosives clearance is carried out like an archeological dig, first with construction equipment and then with manual tools to uncover the detected objects, WITHOUT ANY HANDLING.

Approach and discovery of targets.

Mine disposal operations are sensitive operations.They are a prerequisite for any intrusive operation to be performed on a terrain whose historical analysis and explosive contamination diagnostic have identified targets that are liable to be unexploded explosive ordnances (UXO) or explosive remnants of war (ERW).

DEMINETEC implements a series of explosive operations (described in the explosive safety study) that will be lead by the explosives clearance operator, from relocation of the potential target to it being uncovered through a mechanical and/or manual approach, depending on its depth.

As the main goal is to ensure the safety of property and people, the operations will be carried out with the utmost attention by mine disposal technicians who are trained and certified, supervised by an experienced site manager.

DEMINETEC is capable of providing the guarantees necessary as to the quality and security of these operations, perfectly compliant with regulatory requirements and project owner constraints.

Identification - Expertise.

The phase following the approach and discovery is essential to ensure the quality and security of later operations.It can be broken down into 2 sub-phases:

These 2 phases are carried out by DEMINETEC personnel trained and qualified according to the measures from the French ministerial order dated 23 January 2006.

Explosive Destruction - Neutralization.

Once the explosives are identified, destruction or neutralization operations can be launched.Depending on the type of munitions, the environment, and the conclusions of the safety study, DEMINETEC will be able to carry out all neutralization and destruction operations on site or destruction in a furnace of one or more explosives.

We will be able to ensure destruction in restricted circumstances (notably in an urban environment) by creating or adding compensatory measures to attenuate the effects of detonating several hundreds of kilograms of explosives.

Quality assurance and control.

The key aspects of all explosives clearance projects are quality assurance (QA) and quality control (QC) of our operations in order to guarantee the security of operations to be carried out following mine disposal operations, as per our commitments.All operations carried out by DEMINETEC in diagnostics and explosives clearance are subject to internal quality control (and external control, if necessary) throughout the life of the project, by specially trained and designated personnel.

Quality standards:

Quality assurance:

The following will notably be detailed for these major activity phases:

- Explosive diagnostics:

- - Precision of topographic data

- - Number of measurements per second

- - Sampling interval of measurements

- - Data coverage

- - Technological limits

- Explosives clearance:

- - Technological limits related to the detection devices

- - Conformity or non-conformity of operations by size / depth / consistency of objects depending on each methodology

- - Commitment to corrective action when faced with a non-conformity

- Destruction / neutralization of munitions and explosive remnants of war:

- - Checking there are no residual explosive products

- - Quality assurance of prerequisite check prior to waste removal

- - Commitment in the event of non-conformity

Health and safety

Health and safety are of the utmost importance in all mine disposal operations performed by DEMINETEC

In particular, the following points are handled for each project:

Supervision

DEMINETEC offers quality assurance audits of explosive diagnostic and clearance operations in order to guarantee the project owner that operations are compliant with the regulation in force and the proposals detailed in our technical memory.

-

Audits include, but are not limited to the following activities:

- Revision and evaluation of all relevant documentation covering the qualification and training of workers, quality and suitability of equipment with regards to the issue and the environment of the site in order to meet contractual and legislative requirements.

- Examination and evaluation of the explosive safety study, operating procedures, post instructions and declarations for conformity with regulatory texts.

- Examination of the project management structure to ensure it meets the management, administration and logistical needs of the project.

- Examination and evaluation of the equipment proposed to determine its relevance.

- Examination of maintenance /repair programs for equipment that is essential for safety.

- Auditing of worksites to include the following subjects:

- - Communications

- - Evacuation procedures in case of accident (medical emergency)

- - Safe work practices

- - Explosive safety study (ESP) conformity with operating procedures and safety instructions

- - Internal QA

- - Daily documentation

- - Drafting, compliance, and updating of procedures

- - Structure of the final report / DOE

Clearance certificate

Following each explosives clearance operation, DEMINETEC will produce an explosives clearance certificate.This certificate specifies the operations performed on the site. It shall notably detail:

- The geographical limits (recorded in WGS84)

- The depth of clearance in compliance with the commitments defined in the quality assurance process and the technological limits

- Any reservations that have been reported and georeferenced

- Results of the operations carried out

- Quality control measures taken